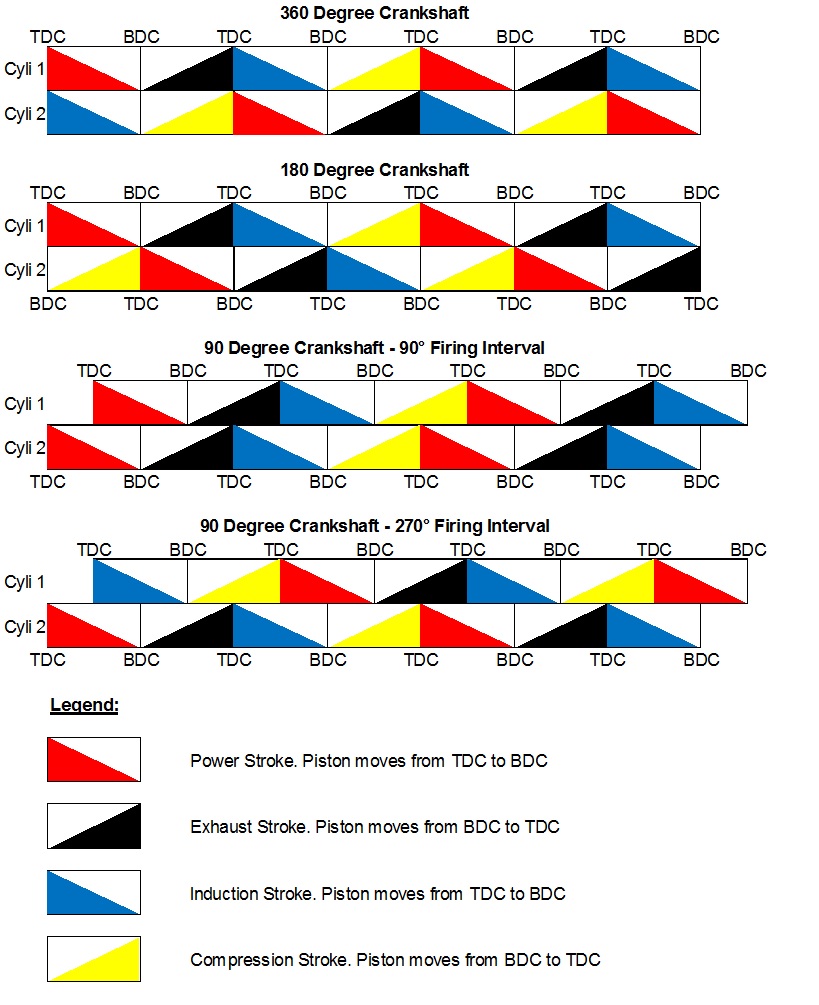

horror of uneven firing intervals? – the manufacturers of even the most vibratory parallel twins showed not the slightest interest in Irving’s proposal despite the relative ease with which they could have converted an engine for test by twisting the crankshaft and camshaft, adjusting the spark timing and fitting a second carburettor where necessary to obviate a mixture bias from overlapping induction phases.

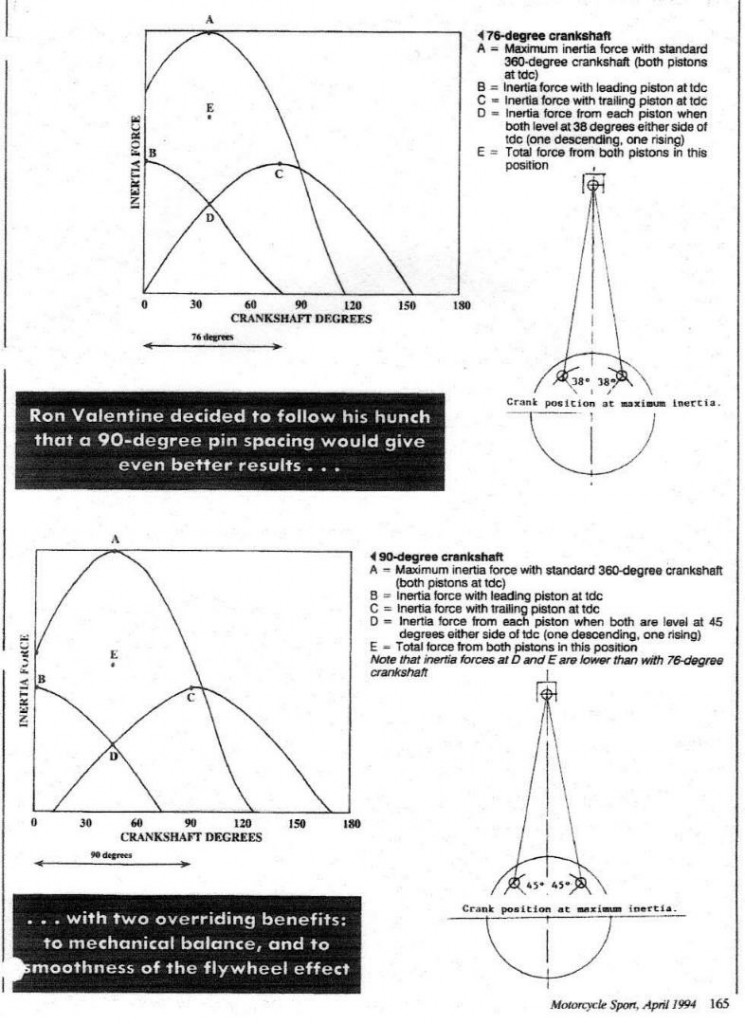

Following the demise of the British industry, it eventually fell to Ron Valentine (and his assistants, including mathematician Tom Oliver) to prove the soundness of Irving’s scheme when (three or four years ago) they completed their second 76° crankshaft for Steve McFarlane’s 952cc (80.5mm x 93.5mm) BSA parallel twin classic racing sidecar outfit. Stretching both bore and stroke of the original A65 engine had aggravated its vibration to the point where the crankcase was in danger of disintegration.

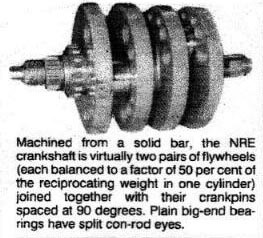

Machined from a solid bar by Dave Nourish, Nourish Racing Engines (NRE), in his Oakham workshop, the new shaft proved to require balancing (to a factor of 50%) as if it were two separate flywheel assemblies joined together. Once that was done, the engines character was transformed. Gone were the frantic shakes. Instead, said McFarlane, there was a slow and lazy throbbing sensation as – to the accompaniment of a pleasant off -beat exhaust lilt, reflecting the 436°/284° firing intervals – the revs soared to 7,000 RPM and the more powerful 1000cc – 1200cc Imp engined outfits were humbled as the BSA won its heat in the Snetterton Race of the Year meeting in 1990.

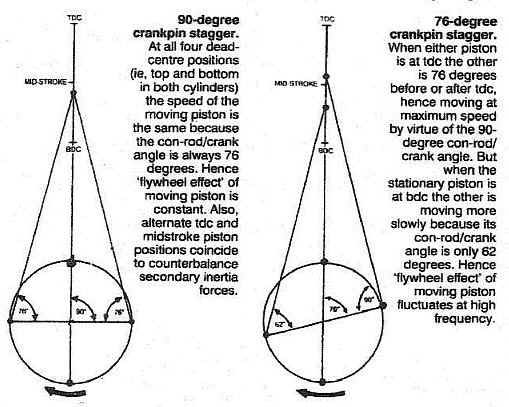

Encouraged that his and Nourish’s sacrifice of valuable time and effort had proved worthwhile, Valentine decided to follow his hunch that a 90° pin spacing would give even better results. True, the instantaneous contribution of the descending piston to flywheel effect, while the other was at TDC, would be slightly reduced because it would be just past its maximum – speed position (big-end angle only76°, not 90°) but there would be two overriding benefits – one to mechanical balance, the other to the smoothness of the flywheel effect.

Balance would be enhanced because the top and bottom dead – centre positions of either piston (where the secondary inertia forces act upward) would coincide with the midstroke positions of the other, where the secondaries act downward. Thus those forces would counterbalance one another at the cost of a small rocking couple.

As to the moving piston’s contribution to the flywheel effect, this would be the same whether the stationary piston was at TDC or BDC (the big-end angle being 76° in both cases). With the earlier 76° pin spacing the ideal “big-end” angle of 90° was achieved only when the stationary piston was at TDC. When it was at BDC and the moving piston was rising, not descending, the angle was only 62°, so the effect was not constant but fluctuated at high frequency. Of these two benefits in favour of 90° pin spacing, the absence of unbalanced secondary forces is clearly the more significant.

When the subject of “cranky cranks” was discussed in Motorcycle Sport three years ago Charles Bulmer suggested that a 180° crankshaft would be even better provided its primary rocking couple were eliminated by means of a crankshaft-driven contra-rotating balance shaft. Quite so, for an engine so designed from scratch by a manufacturer, as with some Hondas.

But what Phil Irving was proposing was the least possible alteration to already established mass-production lines to overcome a serious deficiency in British parallel twins. Given a clean sheet of paper, he had long since shown his own preferences for twin cylinder four strokes: designed just before the second world war, his 600cc Velocette Model 0 vertical twin was a model of smoothness; like its racing stable mate, Harold Willis’ 500cc super-charged “Roarer”, it had contra-rotating geared crankshafts and shaft drive. Later, his postwar 50° V-twin Vincent Rapide ranks as one of the industries greatest designs.