Carburettors are the instruments through which the air flows from the atmosphere into the cylinders of the engine and in the process picks up a mist of gasoline. This mixture of air and gasoline is ignited inside the cylinders and is then what produces the power. The carburettors contain a throttle which is controlled by the driver’s right hand through the twist grip and so sends more or less air/gasoline into the cylinders to suit the driver’s desired engine power output. The trick that the carburettor has to perform is to at all throttle positions ( air flow levels ) provide the right amount of gasoline so to maintain a mixture of approximately 14 parts of air to 1 part of gasoline ( by weight ). That is the relation required for completely combusting the gasoline. Less than 1 to 14 will result in wasting fuel and more will result in higher combustion temperature which is harmful to the internal components of the engine.

The typical carburettor for my engine/era were made by the companies Amal in England, Dell’Orto in Italy, Keihin and Mikuni in Japan and Bing and Solex from Germany.

For my project the natural selection would have been AMAL. However, the company does not seem to produce the models I was considering and they did not bother to reply to my email so they were dropped off my list of options. My engine supplier, the Ducatisti, of course suggested the Italian Dell’Orto’s. I tried to contact the British distributor but I was not able in my poor English to ask the questions that I needed and answer to in such a way that the employee could understand and give me an understandable reply. So the dell’Ortos departed from my list as well. That did not leave me with much choice. Until it struck me that there was another contender out there who I did not know much, not to say anything, about.

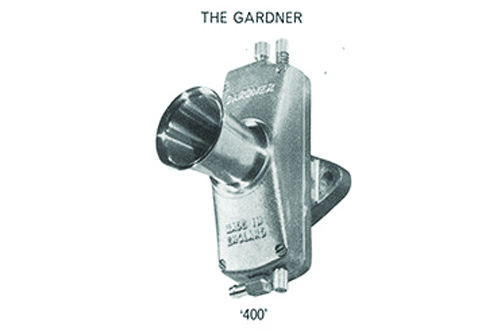

Enter the Gardner Carburettor Company. It was founded and is still run today by Ron Gardner. When I phoned him to talk about my project I told him of my age and that it was maybe crazy to do what I was doing. Then Ron said: “Don’t’ worry son, I am 20 years older than you and still working with my carburettors”. He went on to tell me about his involvement with the engine I am going to use. Gardner was the carburettor that the Weslake company had used as standard on their engines and he sais they consistently produced more power than with any other brand. I think he mentioned 3-5 bhp. Anyway, Ron said that he would not only send the carbs up to my engine man but would also go there himself for the test run and make sure the settings were done correctly. I was immediately sold on his carbs and this is what it is going to be. Gardner 38 mm series 400 units. One per cylinder to be fed from a single float chamber.

Below a picture of the ingenious instrument that a carburettor is and above the picture a link to an article well worth reading about Ron Gardner.

http://www.eurospares.com/tfoale/RonGardnerClassicRacer001.pdf